- 14B, R.N. Mukherjee Road,

3rd Floor, Kolkata-700001 - 91 33-22134528

info@peandt.com

An oil lubricated air compressor draws air into a storage tank with a screw that requires oil to keep the production process running smoothly with maximum efficiency. The oil injected in the compression chamber keeps the system cool by dissipating the heat and acting as a lubricant to lower the friction between the moving parts. Oil lubricated screw air compressors/sometimes called pressure lubricated air compressors, are efficient, reliable, quieter, and last longer. Their ability to work quietly makes them effective for various pneumatic tools and accessories. Oil-lubricated screw air compressors are best suited for industries that do not have stringent requirements for maintaining air quality. The type of oil flooded air compressor suitable for you depends on the application. There are different oil lubricated air compressors, and each has different properties suited to specific jobs.

ELGi’s range of oil injected screw compressors offers maximum profitability due to its low ownership costs. It creates an efficient installation for you with its best time-proven designs, new advanced technological features, and well-equipped manufacturing excellence.

ELGi’s EN Series oil lubricated screw air compressors are known for their reliability, low maintenance requirements, compact design, and small footprint, making them ideal for industrial applications where size, efficiency, and cost matter. The ELGi EN series air compressors have efficient air-oil separation technology and belt drive transmissions that ensure power transmission with good efficiency over long distances. These oil flooded air compressors also come with optional variable frequency drives to match the output with demand, eliminating the frequent load-unload cycle, thereby saving energy. The EN series oil lubricated compressor finds its application in the textile, automotive, paper, and food processing industries. These air compressors are also suitable for small machining and fabrication workshops.

ELGi’s EG Series oil lubricated screw air compressors represent a giant leap in design and performance, with every single component designed for reliability and ease of maintenance. The EG series oil flooded screw compressors come with highly efficient airends equipped with our in-house eta-v profile rotors. Each screw compressor from ELGi is designed and manufactured in compliance with applicable international standards (CE, ASME, UL, and others). The ELGi EG series oil-lubricated screw air compressors are available in three variants to suit your needs. These air compressors are equipped with our in-house eta-V profile rotors, making them energy-efficient. The ELGi EG series oil lube air compressors offer the best-in-class warranty program and operating costs.

The 11-75kW EG series finds application in auto garages, textiles, electronics, engineering, and packaging. The 90-160 kW and 200-250 kW ranges are suitable for automotive, cement, paper and pulp, steel, etc.

The ELGi EG PM VFD Series is designed to provide the best-in-class life cycle cost, ensuring enhanced performance and unmatched energy efficiency even at 100% load conditions, guaranteeing significant savings. The EG PM VFD Series is powered by the ultra-efficient IE5+ ELGi TORQPM and is designed to provide the best-in-class life cycle cost, ensuring better performance and up to a 16% reduction in power consumption. With a range of features, including the Intelligent thermal valve and the advanced Neuron 4 controller that comes equipped with advanced algorithms, the machine efficiently reduces power consumption, resulting in a noticeable decrease in carbon footprint, and therefore positioning itself as the Premium Flagship Machine in the air compressor industry.

The ELGi EQ Series offers unmatched reliability, built tough for a long-lasting performance. Backed by a best-in-class warranty and requiring minimal maintenance, it stands out as a reliable air compressor for industries where size, reliability, and cost are paramount. These air compressors excel in the most demanding and challenging conditions, providing maximum uptime and extended life. Designed for customer-specific applications, the ELGi EQ Series sets the standard for excellence in compressed air maintenance, delivering exceptional value for small and medium enterprises (SMEs). When you need a reliable compressor that won’t break the bank, the EQ Series is your ideal choice.

ELGi’s portable direct drive reciprocating compressors offer superior performance via the uniquely integrated design of motor and top block. Each component is designed for reliability and ease of maintenance, making this model a great investment for customers who require compressed air for light-duty applications.

ELGi’s single-stage belt-drive reciprocating compressors are designed for continuous duty applications. These reciprocating air compressors are reliable workhorses that can generate up to 10 bar g pressure suitable for most of the general engineering and automotive industrial applications.

ELGi’s LD series piston compressors are designed to offer time-proven reliability at low operational speed and assures direct minimum cost with high energy savings. These reciprocating air compressors are ideal for customers looking for significant impact on power cost, very low noise capacity, small air demands, and long running capacity of more than 8 hours a day. Preferred for industries in automobile, textile, food & beverages, paint shot, plastic manufacturing, CNC operation and metal fabrication sectors.

ELGi industrial single and two-stage reciprocating compressors are known for their reliability and performance, making them a preferred choice for industrial applications. These reciprocating air compressors are designed for optimum efficiency while requiring minimum maintenance to meet compressed air needs.

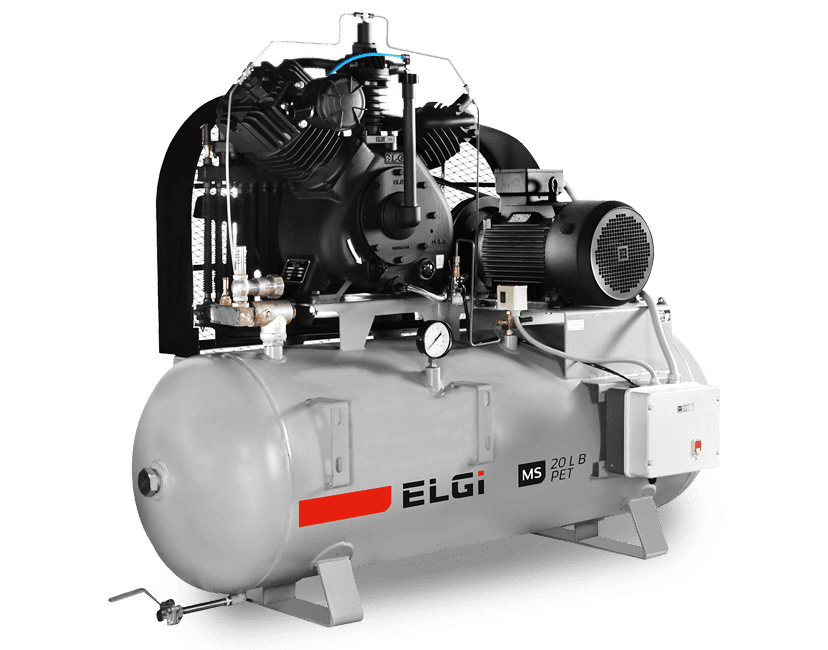

ELGi’s robust three stage high pressure reciprocating compressors come with suction loaders and double poly v belts that make them highly efficient. These reciprocating air compressors are ideal for pet blowing, engine starting, circuit breakers and marine applications.

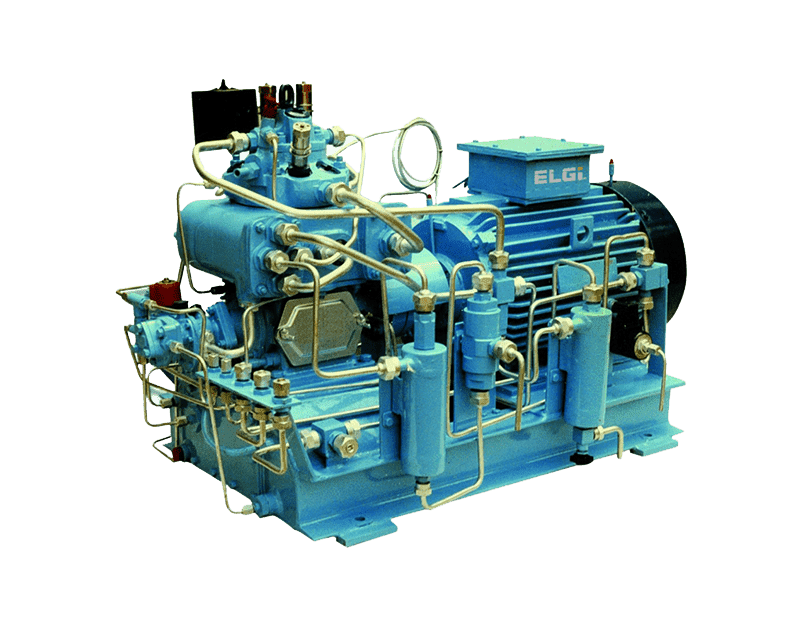

ELGi manufactures custom-built compressors for varied applications including mining, diesel engine starting, hydel and concrete pumps.